Les cartes à collectionner sont passées de simples objets de collection à un marché en plein essor qui s'étend au jeu vidéo., sportif, et des produits de marque. Comme exigence de haute qualité, durable, et les cartes visuellement frappantes grandissent, les entreprises et les créateurs sont confrontés à des défis dans la sélection des matériaux, précision d'impression, et une production évolutive. Le partenariat avec un fabricant d'impression de cartes expérimenté comme Xinyi Printing garantit une production de masse fiable, finitions cohérentes, et le respect des normes internationales. Ce guide décrit le processus professionnel de conception, produire, et fournir des cartes à collectionner qui répondent à la fois aux attentes du marché et aux exigences de la marque.

Différents types de Cartes à commerce

Les cartes à collectionner sont de différents types, chacun servant des objectifs uniques:

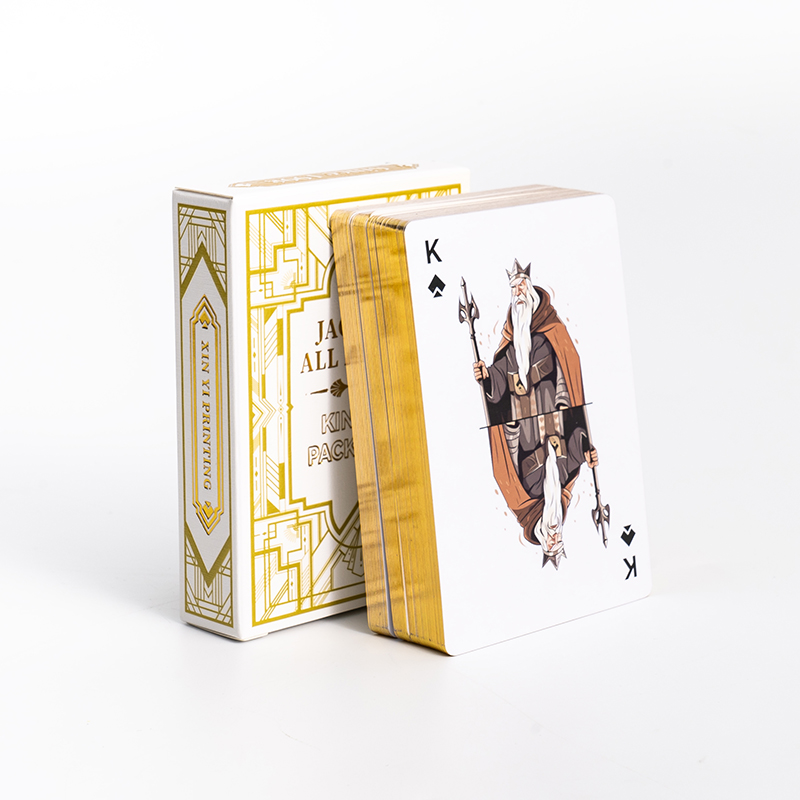

- Jeu de cartes à collectionner (TCG) ou cartes de jeu: Généralement utilisé pour les jeux de table ou de cartes à collectionner, où la durabilité et une qualité d’impression constante sont essentielles.

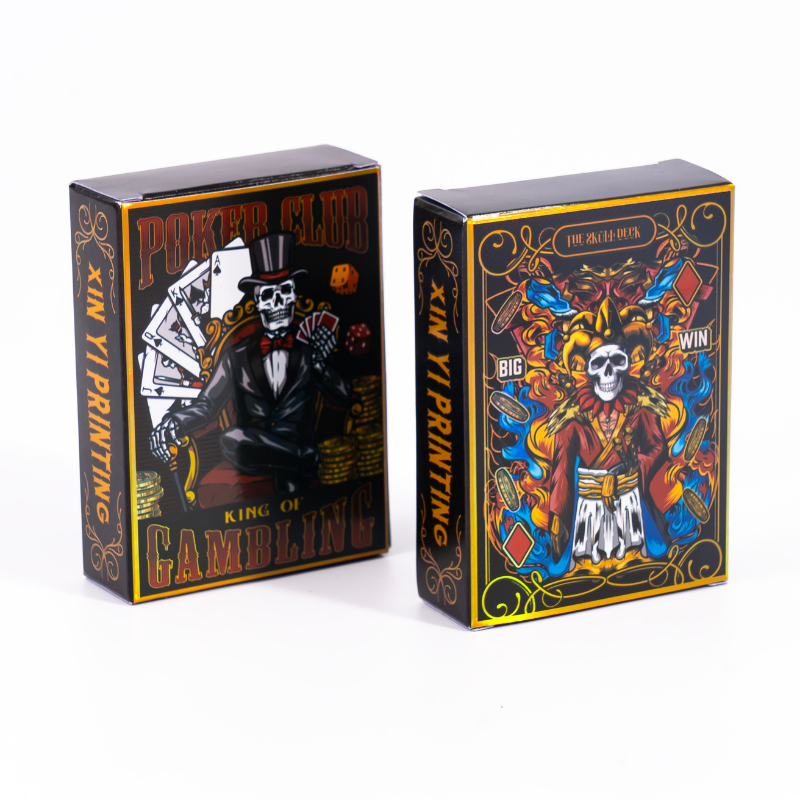

- Cartes de sport: Base-ball, basket-ball, ou des cartes de football pour les fans ou les collectionneurs, nécessitant souvent des finitions brillantes, accents de papier d'aluminium, ou effets spéciaux.

- Cartes de collection: Cartes en édition limitée ou promotionnelles, parfois avec du papier d'aluminium, effets holographiques, ou éléments en relief.

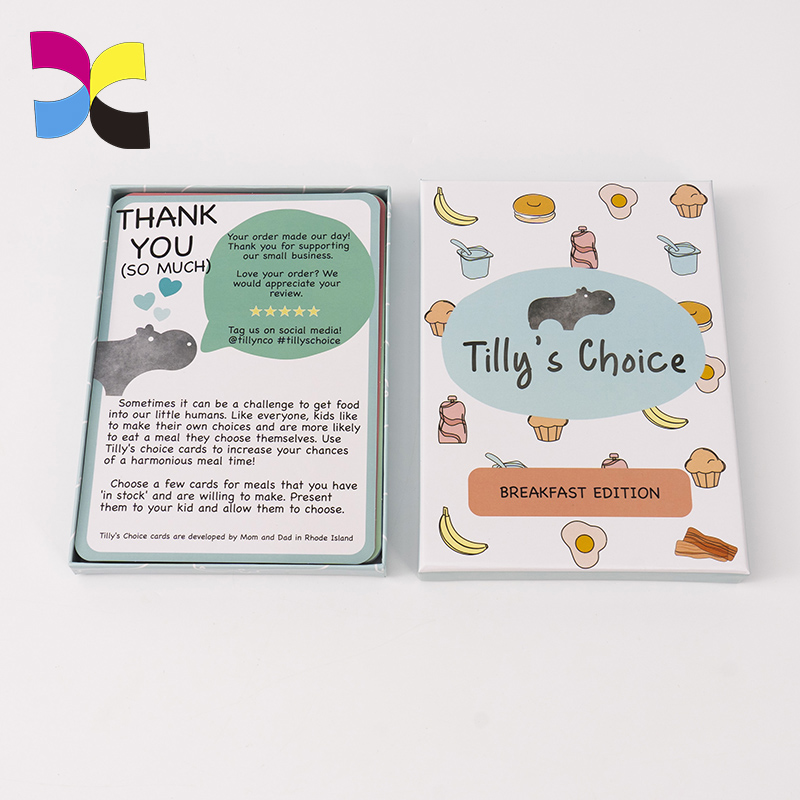

- Cartes de marque éducatives et d'entreprise: Utilisé pour l'apprentissage, promotion d'entreprise, ou à des fins de marque; souvent imprimé sur stock écologique avec des graphiques clairs et un texte lisible.

Chaque type de carte a des exigences spécifiques en matière de papier cartonné., finitions, et échelle de production. À Impression Xinyi, nous fournissons des conseils pour faire correspondre le type de carte avec les meilleurs matériaux et processus pour votre projet.

Étape 1 – Définissez votre projet de carte à collectionner (Utiliser, Taille, et quantité)

La première étape dans la production de cartes à collectionner personnalisées consiste à définir clairement votre projet:

- But: Déterminez si vos cartes sont destinées à un jeu, promotion, ou utilisation pédagogique. Le but affecte les matériaux, finitions, et la durabilité requise.

- Taille et disposition: Tailles standard des cartes à collectionner (par ex., 63 x 88 mm / 2.5 x 3.5 dans) sont couramment utilisés, mais des tailles personnalisées sont également possibles. Un dimensionnement approprié garantit la compatibilité avec les manchons, boîtes, et présentoirs. Vous pouvez référencer notre détaillé Guide des tailles de cartes à collectionner pour dimensions standards et alternatives.

- Quantité: Définir votre cycle de production. Les petits tirages peuvent convenir à l'impression numérique, tandis que les lots plus importants nécessitent souvent une impression offset pour des raisons de rentabilité. Cela éclaire les choix de matériaux, méthodes d'impression, et emballage.

Et Xini, nous examinons vos spécifications et vous conseillons sur la meilleure combinaison de taille, quantité, et stratégie de production pour garantir à la fois la qualité et la rentabilité.

Étape 2 – Choisissez le bon papier cartonné et le bon noyau pour les cartes à collectionner

La sélection du papier cartonné approprié est essentielle pour la durabilité, sentir, et performances d'impression:

Bases du papier cartonné: Le papier cartonné fait référence à une épaisseur, papier rigide utilisé pour les cartes à collectionner. L'épaisseur est généralement mesurée en GSM (grammes par mètre carré) ou pt (points).

Options de base:

- Noyau blanc: Finition lisse, rigidité standard, souvent utilisé pour les cartes TCG ou éducatives.

- Noyau noir: Couche intérieure sombre qui améliore l'opacité, empêche la lumière de passer à travers, et crée une sensation de « claquement » premium.

- Carton / Papier écologique: Options recyclées ou durables, couramment utilisé pour les marques soucieuses de l'environnement ou les cartes éducatives.

Nous fournissons des recommandations basées sur le type de carte: par ex., noyau noir pour cartes à collectionner haut de gamme, noyau blanc pour les decks éducatifs en vrac, et papier écologique pour cartes de marque d'entreprise. Une bonne sélection de titres affecte la longévité, manutention, et impression des résultats.

Étape 3 – Sélectionnez les finitions de surface et les effets spéciaux

Une fois que vous avez choisi le papier cartonné de base, la prochaine étape consiste à décider de l'apparence et du toucher de la surface.. Les finitions de surface et les effets spéciaux peuvent modifier considérablement la valeur perçue de vos cartes à collectionner personnalisées..

| Finition de surface / Effet spécial | Apparence & Impact des couleurs | Durabilité / Résistance à l'usure | Tactile / Sensation visuelle | Cas d'utilisation typiques |

|---|---|---|---|---|

| Stratification brillante | Améliore l'éclat et le contraste des couleurs | Bonne protection contre les rayures et les traces de doigts | Lisse, surface brillante | Cartes de sport, cartes à collectionner |

| Stratification mate | Adoucit légèrement les couleurs, réduit l'éblouissement | Bonne résistance aux rayures, durabilité modérée | Lisse, non réfléchissant | Cartes éducatives, JCC premium |

| Plastification douce au toucher | Couleurs légèrement atténuées | Excellente résistance aux rayures et à l'usure | Velouté, sensation de luxe | Édition limitée, platines haut de gamme |

| Spot UV | Met en évidence les zones sélectionnées, ajoute du contraste | Protège uniquement les zones enduites | Reflets brillants sur fond mat | Cartes rares ou premium, graphiques d'accentuation |

| Feuille froide | Brillance métallique, réfléchissant | Durabilité modérée, peut se rayer s'il n'est pas protégé | Finition métallique lisse | Rare, objet de collection, cartes promotionnelles |

| Feuille chaude / Gaufrage | Brillance métallique, ajoute de la dimension | Durabilité modérée | Texture en relief ou en retrait | Prime, cartes en édition limitée |

| Holographique / Iridescent | Effets arc-en-ciel changeants, fort impact visuel | Durabilité modérée, sujet aux rayures | Attrayant, surface dynamique | Cartes de collection, éditions spéciales |

| Mat + Gaufrage/Débosage | Léger changement de couleur dû à la texture | Bonne résistance à l'usure | Tactile, 3D sentir | Jeux premium, cartes d'entreprise ou cadeaux |

Finitions populaires pour l'impression de cartes à collectionner:

- Stratification mate

- Doux, aspect à faible éblouissement avec un toucher doux, idéal pour les cartes TCG ou éducatives contenant beaucoup de texte

- Réduit les traces de doigts et offre une bonne résistance aux rayures

- Stratification brillante ou revêtement UV

- Haute brillance, couleurs vibrantes, et un contraste plus net, idéal pour la photographie sportive, art de personnage, ou cartes promotionnelles

- Ajoute une bonne protection contre la manipulation et les brassages fréquents

- Toucher doux / finitions en velours

- Luxueux, sensation tactile adaptée aux éditions limitées haut de gamme ou aux coffrets collector

Effets spéciaux et améliorations premium:

- Estampage à la feuille (or, argent, coloré, holographique) pour les logos, frontières, logos, ou des icônes de rareté

- Couches de feuille froide ou de feuille holographique pour obtenir des effets « holo » ou « arc-en-ciel » sur l'arrière-plan de la carte

- Spot UV pour mettre en évidence des domaines spécifiques (icônes, titres, motifs) avec contraste brillant

- Gaufrage / Dégradant pour des textures 3D et un attrait plus collectionnable

Chez Xinyi, de nombreux clients du JCC et des objets de collection utilisent une combinaison de cartes standard mates ou brillantes pour les niveaux de base et de cartes améliorées ou holographiques pour les niveaux rares et ultra-rares., équilibrer le coût et le facteur wow sur l’ensemble de l’ensemble. Notre équipe de production peut vous aider à concevoir une combinaison de finition et d'effet adaptée à votre marque., structure de rareté, et budget.

Étape 4 – Préparer des fichiers prêts à imprimer pour la production de masse

Pour garantir une couleur précise, bords nets, et une coupe constante, vos conceptions de cartes à collectionner doivent respecter les normes professionnelles de prépresse.

- Spécifications du fichier: Assurez-vous que votre illustration correspond aux dimensions de la carte, comprend une purge appropriée (généralement 3 mm), et observe la zone de sécurité pour le contenu critique. La résolution devrait être 300 ppp en mode couleur CMJN.

- Considérations spéciales: Marquez clairement les coins arrondis ou les formes découpées personnalisées. Utilisez des formats vectoriels pour les logos et le texte lorsque cela est possible.

- Erreurs courantes: Images basse résolution, saignements manquants, ou profils de couleurs incorrects.

L'équipe prépresse de Xinyi effectue une vérification détaillée des fichiers avant la production en série, en examinant le fond perdu, résolution, mode couleur, et alignement découpé. Si quelque chose ne va pas, nous partagerons des recommandations ou vous aiderons à ajuster les fichiers afin que vous ne perdiez pas de temps ni de compromis sur la qualité.

Étape 5 – Choisissez la meilleure méthode d’impression: Numérique vs Offset

Quand vos fichiers sont prêts, il est temps de décider comment imprimer vos cartes à collectionner personnalisées. Les deux principales méthodes industrielles sont l'impression numérique et l'impression offset.. Chacun a ses atouts selon votre quantité, budget, et attentes en matière de qualité.

Impression numérique pour cartes à collectionner

- Idéal pour les courses courtes, prototypes, et platines de test

- Configuration plus rapide, ce qui le rend idéal pour les échantillons, campagnes de pré-lancement, et petites commandes

- Coût par carte légèrement plus élevé mais coût d'installation initial inférieur

Impression offset pour cartes à collectionner

- Le meilleur choix pour la production de masse (par ex., 200+ des jeux de cartes ou des séries de cartes à collectionner plus importantes)

- Offre une couleur extrêmement cohérente, détail net, et une excellente rentabilité à grande échelle

- Idéal pour les produits TCG/CCG prêts à la vente au détail, communiqués sportifs, et séries de collection sous licence

En tant que fabricant à grand volume, Xinyi utilise à la fois l'impression numérique et offset dans ses lignes de production de cartes à collectionner.. De nombreux clients commencent par un lot d'échantillons numériques pour confirmer les couleurs, mise en page, et terminer, puis passez à l'impression offset pour le cycle de production principal une fois que tout est approuvé. Notre équipe peut vous suggérer la méthode la plus adaptée en fonction de votre quantité d'impression, plan de distribution, et chronologie.

Étape 6 – De l’épreuvage à la production de masse: Comment Xinyi imprime vos cartes à collectionner personnalisées

Flux de production typique à Xinyi:

1. Consultation et devis

- Vous partagez les spécifications de votre projet: type de carte, taille, quantité, matériels, finitions, conditionnement, et destination

- Nous recommandons les configurations et établissons un devis détaillé

2. Contrôle en amont et vérification des fichiers

- Notre équipe prépresse vérifie vos fichiers et peut vous fournir des épreuves numériques ou des échantillons imprimés

- Pour les projets critiques en matière de couleur ou de grande valeur, nous pouvons fournir des preuves physiques pour approbation avant la production en série

3. Impression et finition

- Une fois les preuves approuvées, nous planifions votre travail sur des presses numériques ou offset

- Après l'impression, les cartes passent par laminage, tamponnage en feuille, Spot UV, ou d'autres étapes de finition comme spécifié

4. Coupe, collation, et CQ

- Les cartes sont découpées à l'emporte-pièce ou guillotinées à des dimensions précises

- Les ensembles sont rassemblés, triés par rareté ou configuration du pack, et vérifié la cohérence des couleurs, alignement, et défauts

5. Emballage et expédition

- Les cartes sont emballées dans des boîtes, boîtes rigides, cartons principaux, ou des présentoirs personnalisés selon vos besoins

- Notre équipe logistique organise l'expédition avec une protection adaptée pour assurer la sécurité de vos cartes pendant le transport.

Avec équipement de production automatisé, une usine de 20 000㎡, et opérateurs expérimentés, Xinyi peut gérer des projets de cartes à collectionner petits et grands avec une qualité constante et des délais de livraison fiables..

Étape 7 – Emballage, Protection, et modules complémentaires

L'impression de vos cartes à collectionner personnalisées n'est qu'une partie du projet. Conditionnement, stockage, et les options de protection ont un impact énorme sur la façon dont votre produit est perçu et sur sa durée de vie entre les mains des joueurs et des collectionneurs..

Solutions d'emballage populaires:

- Boîtes à ranger pour platines simples ou sets de démarrage

- Boîtes rigides / boîtes à fermeture magnétique pour les coffrets collector premium, produits groupés, ou éditions cadeaux

- Boîtes de présentation personnalisées et packs de vente au détail pour les étagères des magasins, boosters, ou des boîtes blaster

Options de protection et de valeur ajoutée:

- Pochettes pour cartes et toploaders pour célibataires de grande valeur

- Livrets de règles, livrets, ou insérez les cartes emballées avec le jeu

- Jetons, tableaux perforés, et des composants de jeu supplémentaires pour les systèmes complets de JCC ou de jeux de société

Parce que Xinyi fabrique également des composants et des emballages de jeux de société, nous pouvons fournir une solution intégrée : impression de vos cartes à collectionner et production de boîtes personnalisées, inserts, et accessoires dans la même installation pour maintenir la cohérence de la marque et la simplicité de la logistique.

Étape 8 - Conformité, Durabilité, et protection de la propriété intellectuelle

Assurer un coffre-fort, conforme, et le processus de production respectueux de l'environnement est au cœur des services de Xinyi Printing.. Nous nous concentrons sur:

- Normes environnementales: Utiliser des matériaux recyclables, encres écologiques, et des processus répondant aux certifications ISO et BSCI.

- Conformité de la production: Adhérer aux réglementations internationales de sécurité pour les produits imprimés, comme CPSIA ou EN71, le cas échéant.

- Fabrication sécurisée IP: Maintenir des flux de travail sécurisés, accès restreint, et des mesures de confidentialité pour protéger les illustrations et les conceptions fournies par le client pendant l'impression.

Note: Xinyi Printing gère la conformité de la production et les pratiques de sécurité IP, mais la responsabilité du droit d'auteur, licence, et l'autorisation de contenu reste la propriété du client.

Quel type de client êtes-vous?

Différents clients ont des besoins différents. Xinyi Printing fournit des solutions sur mesure pour:

- Concepteurs indépendants du JCC: Petites séries, prototypes rapides, et impression numérique avec des options d'emballage flexibles.

- Sportif / Clients du club: Moyennes et grandes séries avec finitions haut de gamme, accents en aluminium ou holographiques, et emballage de marque.

- Éducation / Cartes de marque d'entreprise: Matériaux écologiques, production en vrac, finitions durables, image de marque claire, et des inserts pédagogiques.

Pour chaque scénario, nous fournissons des recommandations sur papier cartonné, finitions de surface, quantité minimum de commande (MOQ), et stratégie de vérification, vous aider à prendre des décisions éclairées efficacement.

Comment obtenir un devis et démarrer votre projet de carte à collectionner personnalisée

Une fois que vous êtes prêt à créer et imprimer des cartes à collectionner personnalisées, la prochaine étape consiste à partager les détails essentiels de votre projet afin que nous puissions préparer une solution sur mesure.

Pour un devis rapide et précis, préparer:

- Type de carte et utilisation (TCG, sportif, objet de collection, éducation, promotion, etc.)

- Taille de la carte, structure du pont, et quantités totales

- Papier cartonné préféré (noyau noir, noyau blanc, GSM spécifique) et finitions (mat, brillant, déjouer, holo, UV)

- Style d'emballage (boîte de rangement, boîte rigide, packs de vente au détail, paquets)

- Pays/région de destination et date de livraison cible

Vous pouvez atteindre Impression Xinyi via notre site Internet fiches produits et formulaires de demande, où notre équipe commerciale multilingue fournit 24/7 réponses, échantillonnage rapide, et mises à jour des commandes en temps réel. Du concept aux decks finis, nous sommes là en tant que partenaire de fabrication pour donner vie à des cartes à collectionner personnalisées de qualité professionnelle.