There are many kinds of paper, from thin sheets for everyday printing to heavy boards for sturdy packaging. Cardstock falls in the middle, offering both flexibility and strength. It’s a favorite choice for creating cards, invitations, and product packaging. But what makes cardstock stand out from other papers? This guide will take a closer look.

What Is Cardstock?

Cardstock, also known as cover stock or pasteboard, is a type of thick, durable paper. It is heavier and more rigid than regular printing paper, yet lighter and more flexible than cardboard. Most cardstock is made from wood pulp, but premium grades may include cotton or recycled fibers for better texture and strength.

Different Types of Cardstock Paper

Cardstock is available in many variations to meet different printing and design needs. Let’s look at the most common types:

- Matte Cardstock: Matte cardstock has a smooth, non-reflective finish, perfect for text-heavy prints or designs with subtle colors. It gives a modern, elegant look without glare.

- Glossy Cardstock: Glossy cardstock enhances vibrant colors and sharp images. It is often used for promotional materials, such as postcards, flyers, and packaging inserts.

- Textured Cardstock: This type includes linen, canvas, or laid finishes, adding a tactile element. Designers often choose textured stock for invitations or luxury packaging.

- Recycled Cardstock: Eco-conscious brands often opt for recycled paperboard. It provides a natural, slightly rough appearance and is made from post-consumer fibers.

- Coated vs. Uncoated Cardstock: Coated cardstock has a sealed surface, which makes colors more vibrant and resists dirt. Uncoated stock absorbs ink better, creating a softer, natural look.

What Is the Size of Cardstock?

Cardstock comes in multiple standard sizes, and knowing them helps you optimize printing and reduce waste.

- 8.5″ x 11″ (Letter size) – Common for U.S.-based printing; often used for greeting cards and marketing sheets.

- 11″ x 17″ (Tabloid size) – Ideal for posters, brochures, or larger folded projects.

- A4 (210 x 297 mm) – The global standard outside North America.

- 12″ x 12″ – Popular for scrapbooking and creative projects.

- Custom sizes – Many printing companies cut cardstock to fit unique product dimensions like board game cards, playing cards, trading cards or packaging inserts.

How Thick Is Cardstock?

Cardstock thickness is one of the main factors that distinguishes it from regular paper or cardboard. It is usually measured in points (pt) or mils, which refer to the thickness of a single sheet.

Most standard cardstock ranges from 8 pt to 16 pt (0.008–0.016 inches), while premium or specialty cards can go up to 20 pt or more. For reference, typical printer paper is about 4 pt, and lightweight cardboard starts around 16 pt, so cardstock sits comfortably in the middle.

What Is the Weight of Cardstock?

Cardstock weight is a key factor in determining quality and usability. Weight is typically measured in pounds (lb) in the U.S. or grams per square meter (gsm) internationally.

| Weight (lb) | GSM (approx.) | Common Use Cases |

| 65 lb | 176 gsm | Greeting cards, simple brochures |

| 80 lb | 216 gsm | Postcards, invitations |

| 100 lb | 271 gsm | Premium business cards |

| 110 lb+ | 298 gsm+ | Rigid packaging, specialty cards |

The higher the weight, the sturdier the cardstock feels. For example, 80 lb cardstock bends easily but still feels premium, while 110 lb cardstock is closer to lightweight cardboard. For custom cards like trading cards or board game decks, 300 gsm is often preferred because it offers excellent durability for frequent handling.

What Is Cardstock Paper Used For?

Cardstock’s durability and print versatility make it a go-to material for countless applications:

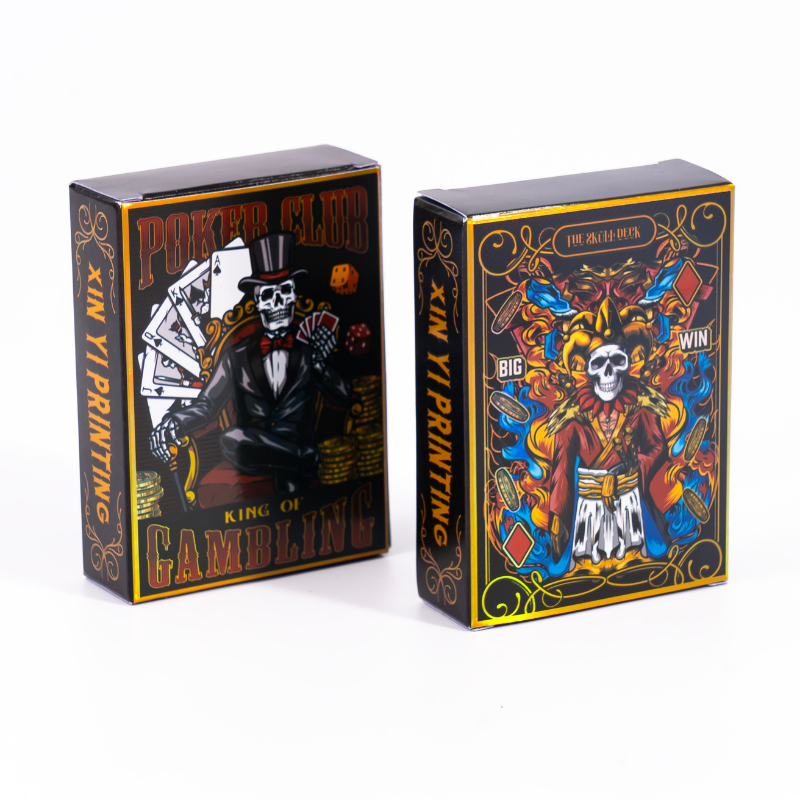

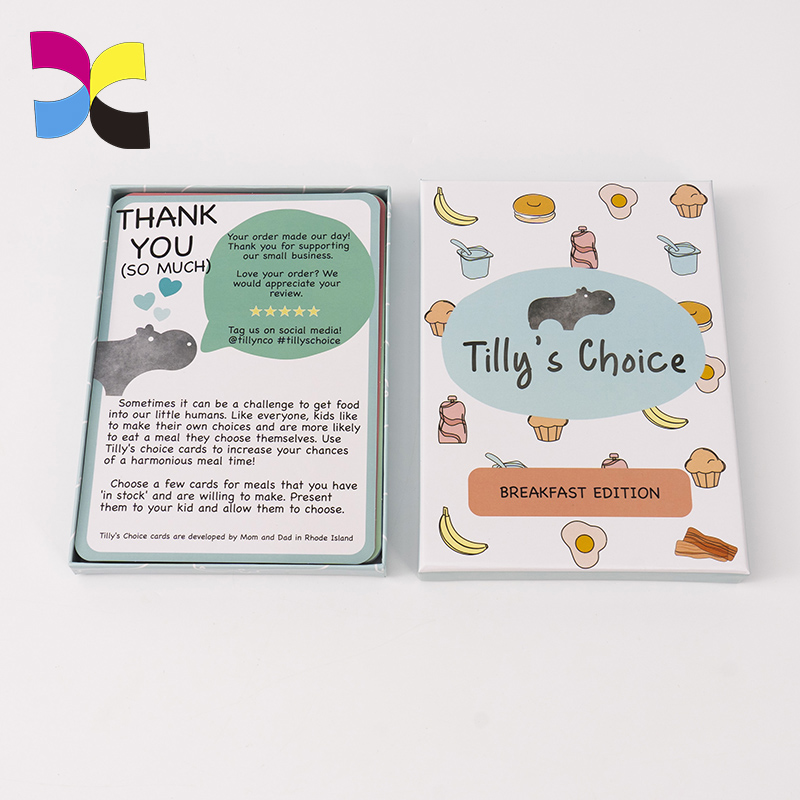

- Game Cards: Trading cards, playing cards, and tarot decks require sturdy stock that withstands repeated handling.

- Business Materials: Business cards, brochures, and presentation folders rely on cardstock to project professionalism.

- Marketing Tools: Postcards, direct mailers, and point-of-sale displays often use glossy or coated stock for vivid colors.

- Creative Projects: Artists and crafters love cardstock for scrapbooking, die-cutting, and custom invitations.

- Packaging: Many small boxes, sleeves, and retail tags use thick cardstock to combine lightweight structure with brand appeal.

Cardstock Finishing and Specialty Printing Options

Finishing techniques transform plain cardstock into a premium product. Here are popular options:

- Foil Stamping: Metallic foil adds a luxurious touch to invitations or premium cards.

- Embossing/Debossing: These techniques create raised or recessed designs, adding texture and dimension.

- Spot UV Coating: Glossy highlights applied to specific areas create contrast and visual interest.

- Lamination: A thin plastic layer improves durability and protects against moisture.

- Die-Cutting: Custom shapes make packaging and marketing materials stand out.

How to Choose the Right Cardstock for Your Project?

Selecting cardstock requires balancing weight, finish, size, and cost. Here’s a simple framework:

- Define Purpose: Marketing materials often need glossy finishes to pop, while invitations or cards benefit from textured stock.

- Match Durability Needs: For packaging or collectible cards, choose 300 gsm or laminated stock for long-term strength.

- Consider Print Method: Offset printing works well for high-volume runs, while digital printing handles small batches and variable data.

- Factor in Budget: Specialty finishes add cost, but they also boost brand perception.

- Think About Sustainability: Recycled or FSC-certified cardstock appeals to eco-conscious audiences without sacrificing quality.

Final Thoughts: Elevate Your Brand with Professional Card Printing

At Xin Yi Printing, we specialize in custom card printing for games, learning, and collectibles, backed by over 27 years of manufacturing experience. We provide a full range of paper types like black core paper, specialty finishes, and packaging boxes to bring your designs to life. Our production line is fully automated—from prepress and printing to binding and hardcover finishing. Equipped with Komori 4-color and Heidelberg 6-color presses, our products deliver vibrant, high-resolution output and consistent product quality.

If you’re planning your next print project, let’s talk about how expert printing can elevate your brand. Click here to contact us.