새로운 보드게임을 개봉할 때, the 게임 보드 is usually the first component you touch, 펴다, 그리고 감탄하다. Its sturdiness, smoothness, and print quality all contribute to the game’s premium feel. But what materials are game boards actually made of? Why do some boards feel thicker, flatter, more durable, or simply more “luxurious,” while others feel rough and resist folding?

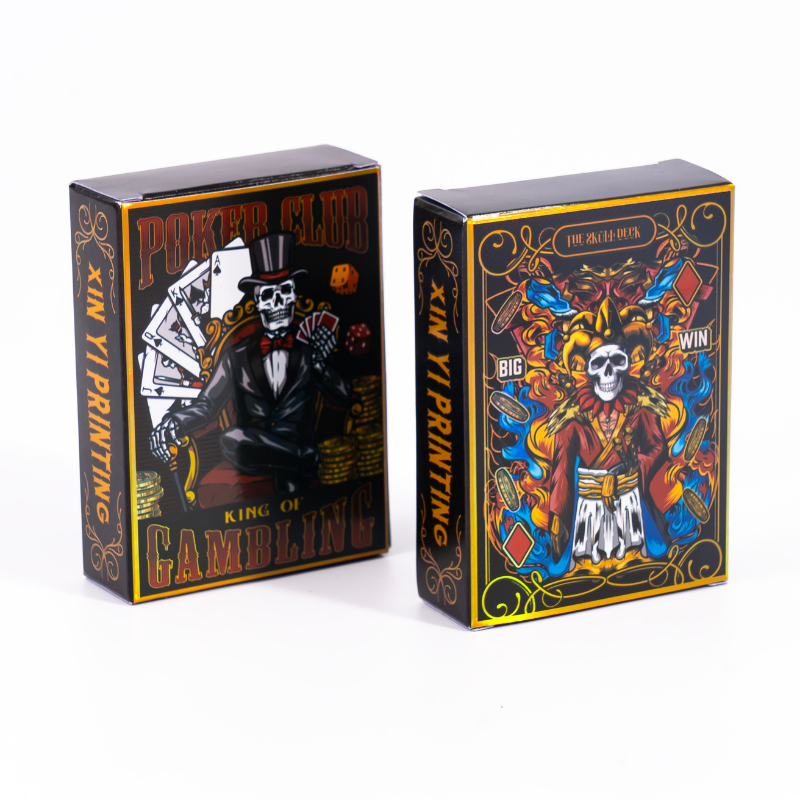

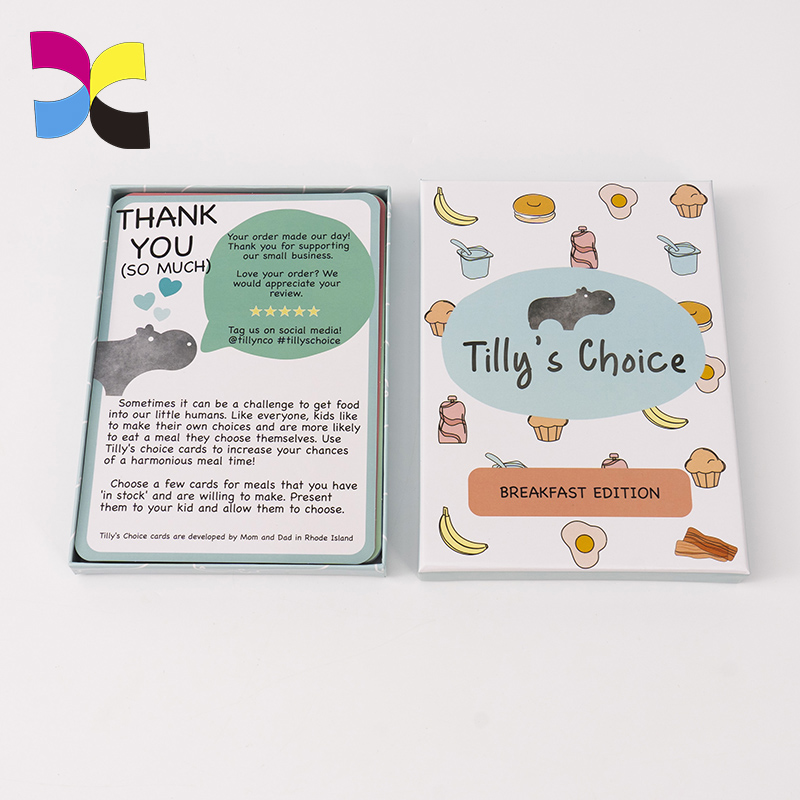

To elevate your board game’s tactile appeal and wow players with its craftsmanship from the moment they hold it, remember: the feel of any board game or card set is like a first impression between people—crucial to the gaming experience. Building your board game brand hinges on ensuring top-notch quality!

~에 신이, we specialize in crafting custom, premium board game components, inspiring both independent creators and top publishers.

Now, join Xinyi as we thoroughly analyze the most common material types and production techniques. Let us guide you in selecting the optimal board material for your next board game project!

보드 게임 보드는 무엇으로 만들어지나요??

Core Material

The thickness of a game board directly affects its durability, rigidity, and how flat it lays during play. Common industry thicknesses include:

1.5 mm – Ideal for entry-level or lightweight games

2.0 mm – The standard thickness for most mid-level board games

2.5 mm – Used for premium, deluxe, or large map boards with a more substantial feel

The core material used for most board game boards is either chipboard or greyboard.

What is Chipboard?

Chipboard is a dense, rigid material made from compressed recycled paper fibers. It is commonly used in board games, book covers, 포장, and other products that require structural support. Chipboard has a smooth, uniform surface and is available in various thicknesses, making it ideal for laminating printed artwork and creating durable game boards.

What is Cardboard?

Cardboard is a broad term used to describe thick, stiff paper-based materials, often used for packaging and shipping. In most industries, “cardboard” specifically refers to corrugated cardboard, which consists of a fluted (wavy) inner layer sandwiched between two flat liner boards. This construction provides excellent strength and cushioning, making it suitable for boxes and protective packaging.

Both are rigid sheets made from compressed recycled paper fibers, offering excellent stability and strength—making them the industry standard for game boards.

Chipboard generally features a more uniform structure with a smoother, lighter-colored surface, providing consistent density and suitability for high-quality printing.

Greyboard, 반면에, is darker in tone and made from recycled pulp. It feels slightly denser and is usually more cost-effective. In board game manufacturing, the two materials are often used interchangeably, as their performance is nearly identical in real gameplay. The main differences lie in surface color and compression method.

Why are The Core Materials for Game Boards so Important?

Regardless of whether chipboard or greyboard is used, the board is always wrapped with printed art paper and finished with protective lamination to ensure long-lasting color, smooth handling, and structural durability through repeated folding and frequent gameplay.하지만, choosing the right core material is still critically important, because it directly affects the board’s rigidity, resistance to warping, overall lifespan, and the premium impression players experience when they unfold the board. A well-selected material ensures that the board lays perfectly flat, withstands humidity changes, holds up against heavy use, and delivers the level of quality that matches your game’s production standards.

Creative Aspects of The Game Board

1.Surface Material: Printed Art Paper

After forming the core corrugated cardboard, both sides of the game board are covered with art paper bearing the printed design.

Common Paper Types:

157gsm C2S Art Paper—Industry Standard

128 gsm Art Paper — Slightly thinner but smooth surface

170 gsm Premium Art Paper — Used for luxury craftsmanship

Printing Processes:

Offset Printing — Vibrant colors, exceptional quality

Digital Printing — More efficient for small-batch samples

UV Printing — Special edition products, rich colors with ultra-durable finish

This printed layer lends the game board its visual appeal—maps, grids, terrain, 아이콘, or illustrations.

2.Protective Coatings: Lamination and Surface Treatments

Similar to the surface treatments applied to books, 카드, and packaging boxes, game board surfaces also require lamination and other treatments to protect printed designs and enhance durability. Common coating processes include the following:

광택 라미네이션:

Gloss lamination uses high-gloss resin as its core component, combined with solvents. After curing, it forms a highly transparent, high-reflectivity surface coating.

무광택 라미네이션:

Matte lamination uses a matting agent on a varnish base to disrupt the uniformity of light reflection on the coating surface. After curing, it creates a low-reflectivity, foggy matte finish.

엠보싱:

This post-press technique uses high-temperature, high-pressure dies to create raised or recessed three-dimensional effects on printed surfaces. Achieving a tactile relief and visual depth without ink, it’s often used to enhance artistic appeal and brand recognition. Examples include fabric-like crosshatch textures that resist scratches while offering a luxurious, refined feel—a preferred choice for premium publishers.

Anti-Scratch Laminations:

Premium upgrade coatings with exceptional scratch resistance. These coatings define the tactile experience of the board and its durability under intense gameplay.

3.Board Folding Types

Most manufacturers support 39-inch × 27-inch game boards. Beyond this size, you’ll need custom equipment and incur higher costs.

Common dimensions include:

15-inch × 15-inch: Classic square format (similar to Scrabble)

20-inch × 20-inch: Popular for strategy games

20-inch × 30-inch: Games requiring larger playing areas

4.Premium and Unique Board Materials

Some manufacturers opt for distinctive materials to set their products apart.

Magnetic Boards: Incorporate a thin magnetic layer compatible with magnetic pieces, making them ideal for travel games.

Foam Core Boards: Lightweight yet substantial, used for prototypes or large-player boards, though less durable than particleboard.

MDF/Wooden Boards: Suited for deluxe or heirloom editions, offering exceptional rigidity but being costly and bulky.

PVC/Plastic Boards: Waterproof and durable, common for outdoor or bar-friendly games. These niche materials significantly elevate premium aesthetics.

From surface materials and protective coatings to folding formats and premium substrate options, every creative aspect of a game board contributes to its overall quality and player experience. The choice of materials not only defines visual impact but also determines durability, playability, and the perceived value of the game itself. By understanding these components and selecting the right combinations, creators can craft game boards that are visually striking, structurally reliable, and perfectly aligned with the gameplay experience they aim to deliver—whether for mass-market titles or high-end collector editions.

Conclusion: The board is the heart of a board game.

Though seemingly simple, every sturdy crease and vibrant pattern on a game board reflects meticulous material selection and exquisite craftsmanship. From cardboard thickness to lamination types and specialized finishing options, understanding these material properties will help you design games with comfortable tactile feel and outstanding play experience.

Whether you’re a game publisher, designer, or simply a player who appreciates well-crafted components, understanding the materials that make up a game board allows you to appreciate the craftsmanship behind your beloved tabletop games.

Partnering with professional board game manufacturers helps your brand stand out with unique appeal.