Depuis des siècles, les cartes à jouer font partie intégrante du divertissement humain. Des jeux de cartes de poker classiques aux jeux de cartes à collectionner modernes, cartes à collectionner, et accessoires de table personnalisés, la production de cartes est à la fois un art et une science. Derrière chaque pont se cache l'essence de l'ingénierie des matériaux, technologie d'impression, et fabrication de précision.

Ce guide approfondira le processus détaillé de production de cartes, les matériaux employés, et pourquoi ces choix sont cruciaux pour la durabilité d’une terrasse, sensation de brassage, attrait visuel, et l'expérience de jeu globale.

De quoi sont faites les cartes à jouer?

Comme nous le savons tous, le matériau le plus classique pour jouer aux cartes est le papier. Mais saviez-vous? Outre le papier, il existe de nombreux autres matériaux utilisés pour fabriquer des cartes à jouer. De plus, le papier lui-même se décline en de nombreuses variétés, ce qui donne différents types de cartes à jouer. D'abord, Explorons le type le plus simple : jouer aux cartes en papier:

Papier de base noir, most commonly used for: cartes à jouer, casino cards, TCG cards, cartes de jeu de société. Features a black inner core that allows light transmission, providing a solid feel during shuffling and cutting. Typiquement 300-330 gsm in thickness.This article:Qu'est-ce que le papier cartonné à noyau noir ?? details the uses of substandard cardboard; you can refer to it.

White Core Paper, featuring a softer white inner layer, is commonly used for educational cards or children’s cards. Thickness ranges from 280-320gsm, offering lower cost and vibrant color saturation.

Blue Core Paper, similar to black core paper, also prevents light transmission. It is very common in assigned factories, boasts low light transmission, and maintains consistent quality.

Linen Finish Paper,Offers a more premium tactile experience. Essentially black or white core paper with an embossed texture, commonly found in high-end playing cards, magic cards, and TCGs. Présente des lignes de surface fines pour une durabilité accrue, lavage et coupe plus doux, collage réduit, et une sensation plus professionnelle.

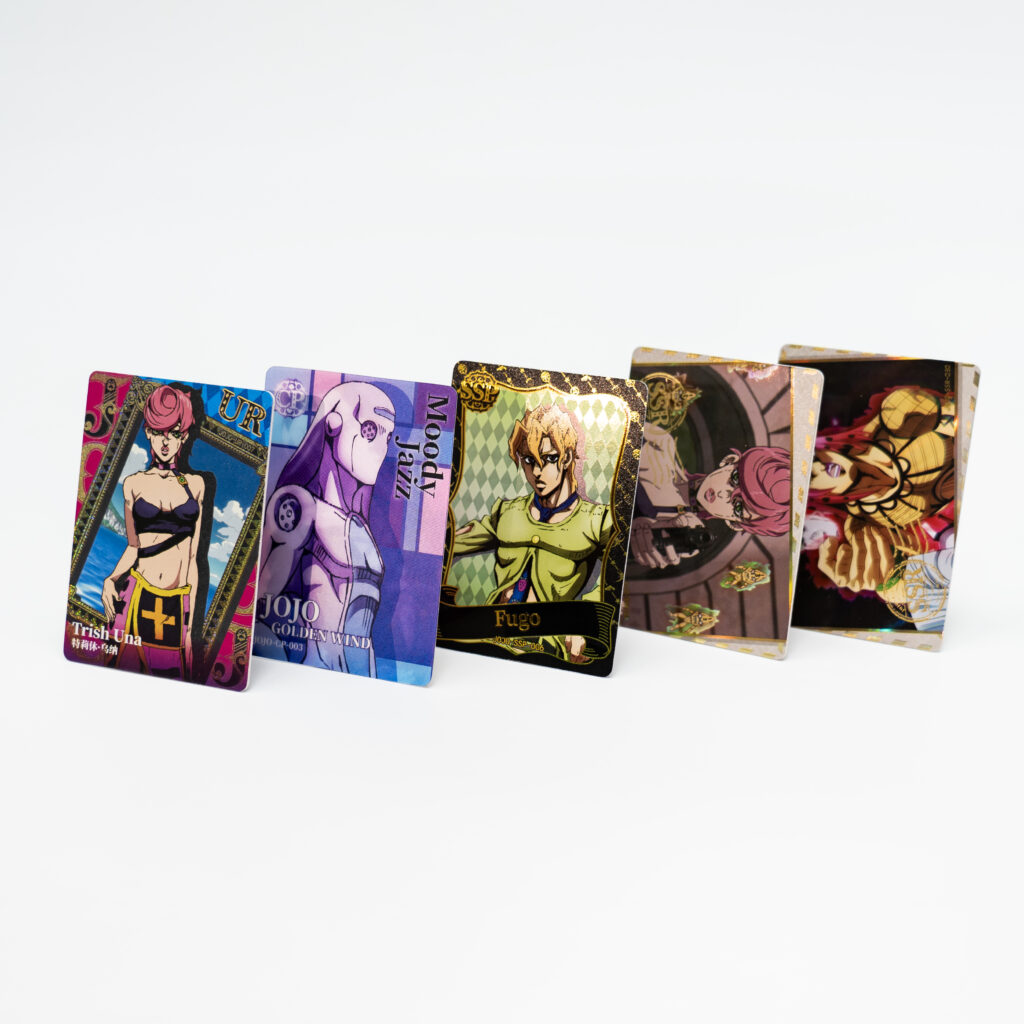

Papier cartonné spécialisé est utilisé pour les cartes à collectionner et les cartes aveugles avec des éléments de conception forts, comme le papier holographique, Papier métallisé, Papier Nacré, Papier cartonné pailleté, etc.. Ceux-ci offrent des effets visuels saisissants et conviennent aux, cartes en édition limitée.

Suivant, Jetons un coup d'œil aux cartes fabriquées à partir d'autres matériaux:

- Cartes PVC

Commun pour les terrasses étanches, cartes de style casino, et des cartes éducatives durables.

- Cartes en plastique PET

Plus écologique que le PVC, avec une excellente clarté.

- Cartes en métal

Fabriqué en aluminium ou en acier inoxydable, souvent pour des coffrets cadeaux haut de gamme.

- Cartes en bois

Gravé au laser ou imprimé pour des decks artistiques et écologiques.

- Cartes acryliques

Plastique haute transparence utilisé dans les produits dérivés d'anime et les cartes d'affichage.

Comment sont fabriquées les cartes à jouer?

Étape 1:Concevoir votre jeu de cartes

Connaissez votre numéro de carte:Lorsque vous décidez de créer votre propre jeu de cartes à jouer, la première étape est étonnamment simple, mais que de nombreux débutants négligent souvent. Beaucoup se lancent directement dans la conception de leur jeu personnalisé sans tenir compte du nombre de cartes.. Mais le décompte total constitue la base de tout le projet. Sans chiffre clair, vous pourriez manquer d'idées en cours de conception ou vous retrouver avec un style incohérent alors que vous vous efforcez de combler des lacunes inattendues.

Un deck standard contient 54 cartes, donc si vous souhaitez reproduire un design traditionnel, le compte est déjà réglé. Mais si votre objectif est de créer un deck non traditionnel ou entièrement original, choisir le nombre exact de cartes est crucial. Il détermine le nombre de concepts ou d’illustrations uniques dont vous aurez besoin.

Une fois le nombre de cartes défini, l'étape suivante consiste à créer une liste numérotée documentant chaque carte que vous prévoyez d'inclure. Cette liste vous servira de feuille de route, vous guider tout au long de la phase de brainstorming et vous conduire naturellement vers la deuxième étape du processus créatif.

Choisissez la taille de la carte que vous souhaitez personnaliser:Vous voulez créer votre propre jeu de cartes? Besoin de connaître les dimensions correctes des cartes à jouer? Nous avons soigneusement compilé ce guide complet couvrant différentes tailles de cartes à jouer pour vous aider à faire le meilleur choix pour des cartes parfaitement imprimées.. Allez voir!

jeu de cartes de poker

54 Cartes

4 Costumes, 9 Nombres, 5 Cartes faciales

Jeu de cartes de tarot

78 Cartes

22 Arcanes majeurs & 56 Arcanes mineurs

Plate-forme personnalisée

N'importe quel nombre de cartes

Étape 2:Sélection du papier

Sélectionnez votre papier de carte à jouer en fonction de l'utilisation prévue. Le papier standard est généralement recommandé. Pour plus de détails, se référer au chapitre 1 de ce document.

Étape 3:Choisir la finition de surface

Cette étape détermine la sensation, durabilité, et résistance à l'usure des cartes à jouer. Les techniques de traitement courantes comprennent:

Revêtement brillant

Forme une fine couche protectrice, améliorant la saturation des couleurs et réduisant l'usure.

Laminage (Brillant/Mat)

Ajoute de l'épaisseur et de la protection. La stratification mate offre une sensation douce au toucher, tandis que la stratification brillante améliore la brillance.

Texture de lin (Processus de gaufrage)

Imprime la microtexture à l'aide de rouleaux métalliques, améliorant la fluidité du mélange et réduisant le collage des cartes.

UV ou UV ponctuel

Utilisé pour les cartes à collectionner ou premium pour créer des effets brillants à contraste élevé.

Estampage holographique ou à feuille

Couramment appliqué aux decks en édition spéciale, cartes promotionnelles, ou des cartes rares dans les jeux de cartes à collectionner.

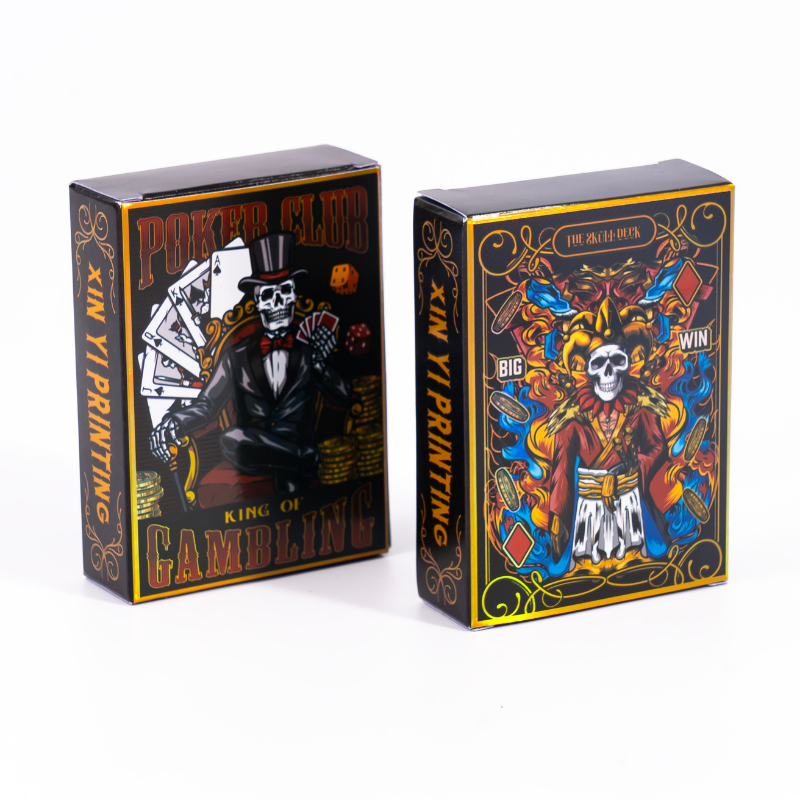

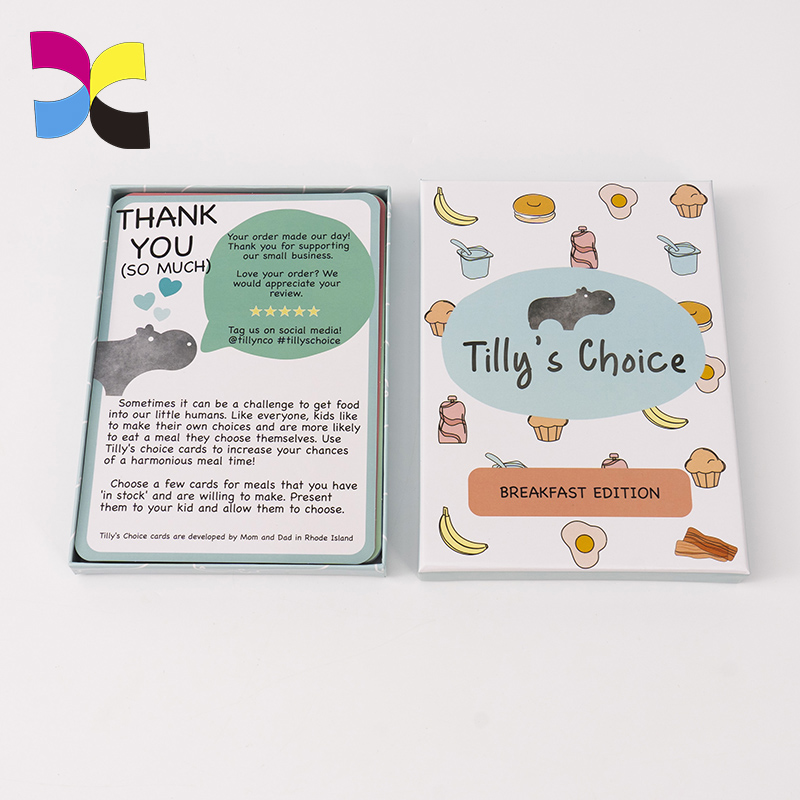

Étape 4:Choisir un emballage de boîte

Xinyi offre une grande variété de styles de boîtes, selon vos besoins, nous l'avons.

Étape 5:Imprimer les cartes avec les meilleurs

Notre équipe d’impression professionnelle offre un service méticuleux. À le, vous pouvez nous confier vos fichiers de conception pour vérification de la mise en page, ajustements de la ligne de purge, Calibrage de la valeur de couleur CMJN, Et plus. Notre usine produit des épreuves basées sur vos fichiers pour confirmer les options papier. Nous imprimons ensuite sur des presses professionnelles Heidelberg huit ou six couleurs.. Après l'impression, on procède à la découpe: les grandes feuilles sont pliées le long de lignes prédécoupées, puis découpé avec précision en cartes individuelles. Les cartes nécessitant des coins arrondis retournent à la machine pour un, bords cohérents. Les dernières étapes concernent l'assemblage et l'emballage. Les méthodes d'emballage courantes incluent le scellage en plastique/le thermoscellage, emballage en boîte de papier, avec des types de boîtes, y compris des boîtes repliables, boîtes rigides, ou caisses métalliques. L'usine propose également une personnalisation intégrée des boîtes d'emballage, pochettes de rangement, et contenants en plastique.

Xinyi utilise en permanence des innovations en matière de fabrication, utiliser des matériaux respectueux de l'environnement tels que des substrats en papier recyclé, plastiques d'origine végétale, et encres à base de soja pour l'extraction des matières premières. L'estampage numérique permet une impression à grande échelle, tandis que diverses techniques d'impression de cartes créent parfaitement vos cartes.

Bien qu'apparemment simple, les cartes à jouer impliquent une ingénierie de précision, matériaux spécialisés, et techniques avancées. De la sélection du bon papier aux traitements de surface, laminage, et coupe de précision, chaque détail compte.

Comprendre la fabrication des cartes à jouer aide non seulement les joueurs à mieux apprécier leurs jeux, mais donne également du pouvoir aux concepteurs., éditeurs, et les marques pour prendre des décisions éclairées lors de la production de cartes personnalisées.

Conclusion

Jouer aux cartes peut sembler simple, mais leur création implique une ingénierie minutieuse, matériaux spécialisés, et des procédés de fabrication avancés. De la sélection du bon papier cartonné à l'application des finitions, couches de stratification, et coupe de précision, chaque détail compte.

Comprendre comment les cartes sont fabriquées aide non seulement les joueurs à apprécier leurs decks, mais donne également du pouvoir aux concepteurs, éditeurs, et les marques doivent prendre des décisions éclairées lors de la production de leurs propres cartes à jouer personnalisées.

Partenaire avec Xinyi! Nous proposons des options de personnalisation uniques.